Wire rope lubricators and wire cleaners as well as other modern tools are essential in the complex field of maintenance for cables. Efficiency and longevity are vital. These innovative devices have a crucial role to play in ensuring the smooth operation and long-lasting life of cables throughout various industries. This article focuses on the significance of wire rope cleaners and lubricators in cable maintenance. We also look at their advantages and uses.

Understanding Wire Rope Lubricators:

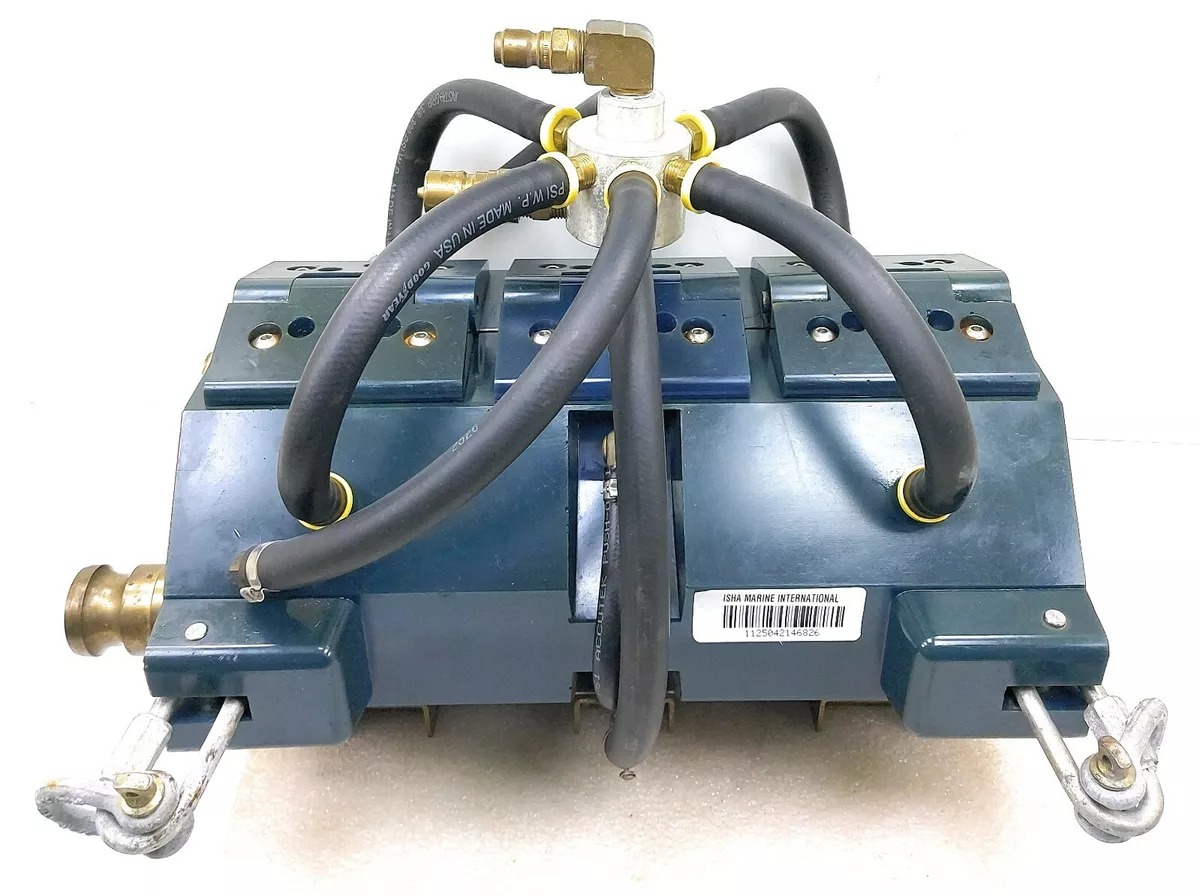

Wire rope lubricators are specialized devices designed to apply lubrication to wire ropes systematically. This is essential for the prevention of corrosion, decreasing friction, and increasing the overall durability of the cable. The lubricator distributes lubricant evenly along the length and widening of the wire rope to protect it from wear.

The role of wire cleaners in Cable Maintenance:

Cleaning wires and cable cleaners are both essential to maintain clean cables. These cleaners are intended to remove fluids, contaminants and dirt that get on cables during various activities. Wire cleaners are vital for harsh environments, in which cables could be subjected to extreme conditions. They are designed to ensure maximum performance and help prevent harm to the cable. Click here Cable Cleaner

Optimizing Cable Lifespan:

Combining wire cleaners with greasers for wire rope can help extend the length of a cable. When you apply lubrication consistently using wire rope lubricators and removing dirt with wire cleaners the cables are shielded from the damaging consequences of corrosion, friction and external factors. This preserves the integrity of the cable and leads to improved efficiency and lower maintenance costs.

Application of efficiency:

Wire Rope Lubricators are made to be user-friendly and efficient in their application. They can be utilized on a variety of sizes and kinds of wire ropes. This allows for versatility when it comes to cable maintenance. The lubrication process is automated and applied in a systematic way, which ensures consistency and avoiding the chance of uneven coverage.

Ability to adapt to challenging environments

In industries where cables are exposed challenging environments, such as the ones used in construction, drilling or maritime operations the flexibility of wire rope lubricators and cleaners is essential. These devices are designed to endure harsh conditions and provide the most reliable tools for maintaining cables with a variety of settings.

Cost-Effective Maintenance Solutions:

The proactive approach to cable maintenance by making use of wire rope lubricators and wire cleaners has proven to be a cost-effective solution over the long term. The initial investment for these tools is low compared with the future costs, such as repair and replacement of cables because of improper maintenance.

Conclusion:

Lubricators for wire ropes along with wire cleaners, are guardians of cable integrity. They provide precision, longevity and optimal performance in all industries. Removal of contaminants and the use of lubricants contributes to the longevity and preservation of cables. This decreases maintenance and increases operational efficiency. Cables are still in use in the most critical sectors, therefore using cable maintenance tools that can be used to ensure reliability and efficiency is a must.